Europe’s fifth largest rating agency, Cerved Group, has produced an independent report after analysing 1.850 companies in the agro-industrial sector on environmental, social and economic sustainability. The first company in the fruit and vegetable sector in Italy was IORI (second in the overall Italian ranking). During the event for the presentation of the results, the company was rewarded in the presence of the Minister of Agriculture.

Tradition

Since 1957 we have been growing vegetables in the fertile lands of the former Fucino Lake, at the gateway to the oldest Italian National Park. In 1984 we built our first plant to package carrots in bags, crates and trays. Since the early 90’s we have been collaborating with supermarket chains and grocery retailers in Italy and in the main European countries. In order to ensure the freshness and availability of the carrots all year round, we have extended the production to other Italian regions that benefit, in some months of the year, from milder temperatures . Since 2015, we have been distributing the “Altopiano del Fucino Carrot”, a Protected Geographical Indication product (P.G.I.). Knowledge of the territory, cultivation techniques, storage and packaging processes guarantee our customers healthy and safe carrots in accordance with the current rigorous regulations. The expertise accumulated in over 60 years of business activity is now in the hands of the third generation of the IORI family.

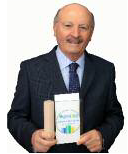

Prof. ANTONIO IORI with the National Sustainability Award

Innovation

We have defined three concrete objectives for our concept of sustainability:improve the organoleptic characteristics and shelf life of the fresh product; optimize the selection and packaging processes; develop new articles from by-products. To secure the necessary skills, we have initiated collaborations with Universities and Research Institutes, hired young graduates and activated specific training courses for employees. Since 2016, we have introduced new production methods with low environmental impact and updated the procedures for product storage in the 4,000 m3 refrigerated storage rooms. In 2020, we completed the new sorting and packaging line that generates significant water and energy savings. Last Christmas we presented the gourmet compotes and sauces made with the smallest and most tender carrots. Starting from next summer we will offer two more products derived from the residues of our processing cycles, currently in the testing phase. During 2021 we will also replace the power supply of the new plant with renewable energy sources. With humility and discretion we will continue to listen to the valuable suggestions of our business partners, who every day deal with increasingly aware and demanding customers and provide us with continuous suggestions for improvement. With dedication we will continue to build a business system open to innovation that offers opportunities for development and creates benefits for the community and the environment.